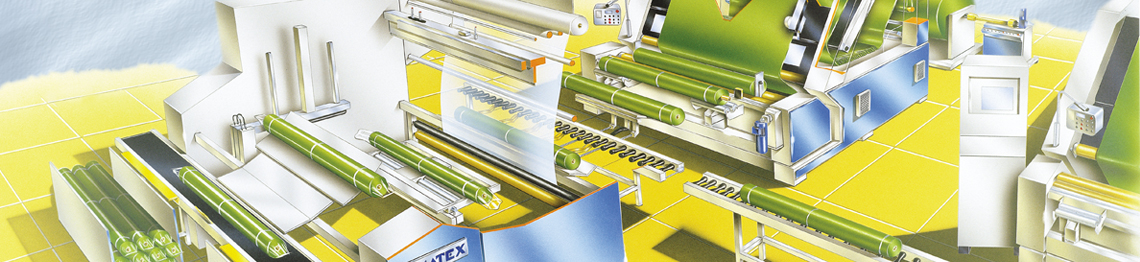

Software for the marking of the defects on the fabric with touch screen monitor.

With database od costumer, article, defect ect; and automatic calculation of the second choice

Automatic roll label 10x10 printing or packing list 20x30

New Software for inspection machine system, interfaced with the PLC allow to mark up to 20 different fault of the fabric,

•Roll code ( Only reader ): it displays the number of the roll, that will be printed on the label

•Lot’s number : it usually displays the lot’s number of: big roll, or folding; in entry to the inspection.

•Roll’s progressive: Progressive number of the rolls worked. After having set the initial value this number it automatically increased when is closed a roll.

•Weight (Only reader ): Weight on the balance.

•Actual lenght (Only reader): Actual lenght of fabric read by PLC.

•Automatic stop to costumer meter set .

•Article code in work.

•Article: Description of the article(material).

•Gross width

•Net widthof the article.

•Color of fabric

•Sketch: Possible printout or sketch report on the fabric.

•Weight/mq

•Finishing 1 / 2 : Possible Finishing of the article.

•Costumer: Name of the costumer.

•Costumer order.

•User (Only reader): name of login.

•Communication with PLC.

•Fabric widht reader

•Set type of fabric entry

•Packing list

•Comunication easy and fast whit mouse

•Parameter inserted with keyboard