Precision plaiting machine

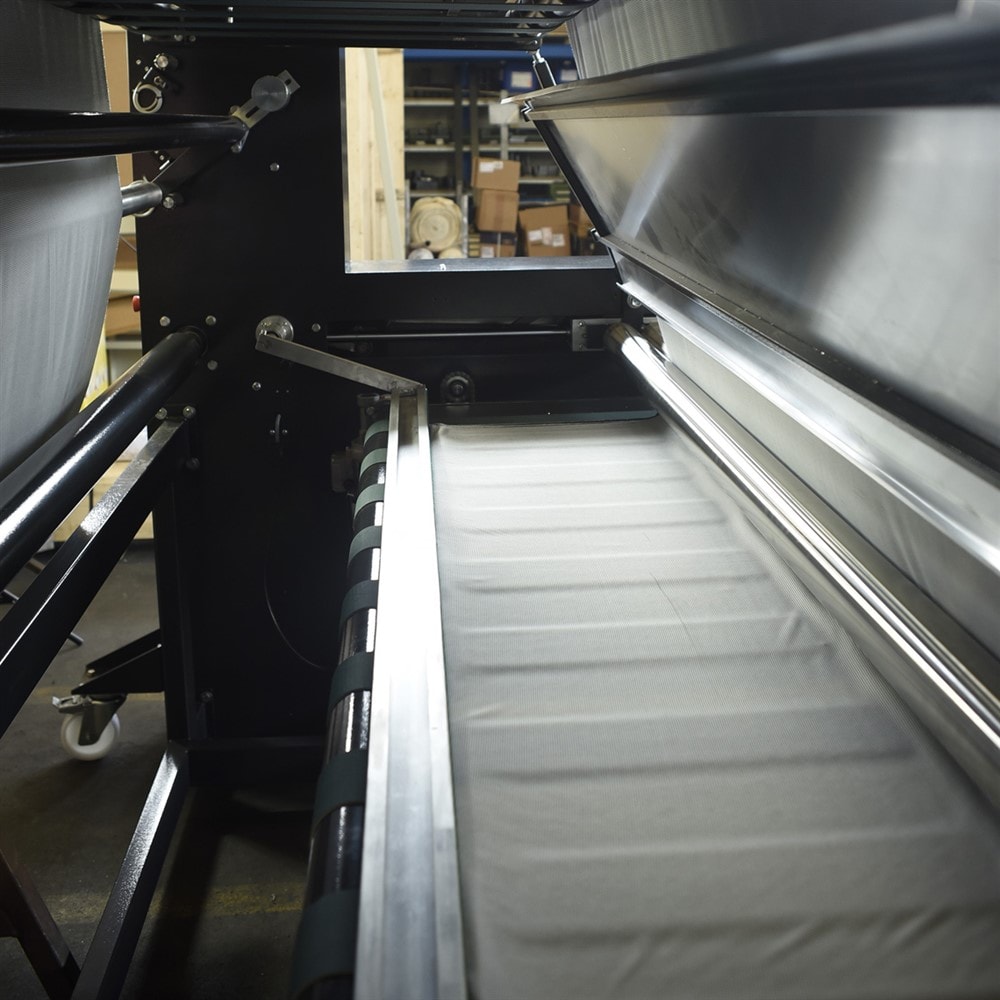

The FP machine is a precision plaiting machine for open or tubular stretch fabrics, mounted on wheels for easy movement within the department, to be positioned as an end-of-line machine after a compactor or a production machine.

A motorized conveyor belt carries the fabric from a previous line toward the plaiting rollers. A constant-motion linkage moves the plaiting rollers horizontally, transmitting a constant cycle, allowing the fabric to be plaited precisely over another conveyor belt.

Once the height of the pack, set by the operator, or the desired length has been reached, the machine automatically cuts the fabric just before the plaiting rollers.

The conveyor belt on which the fabric pack is formed automatically unloads the fabric just finished and begins forming a new one.

The function of weighing the package just before cutting is also available, to create the reference label of the fabric just processed.

Because it depends on a mechanical linkage, the lenght of this machine's plait is fixed. Discover the FPA version for an adjustable plait lenght.

Italiano

Italiano