Technical features

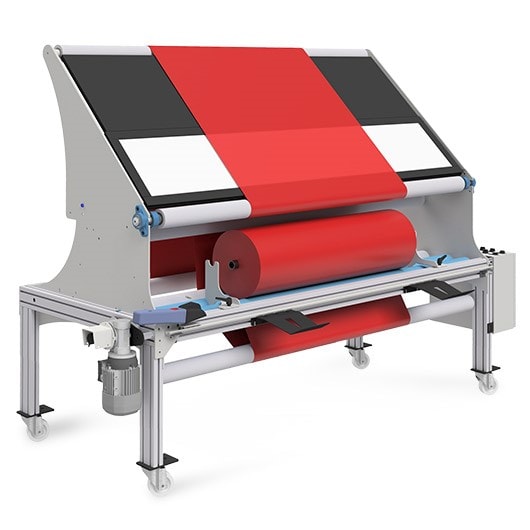

The winding machine mod. AR PP are designed for companies that need to cut fabric samples from their stock rolls. They are quick to feed-in and offer many of the same advantages and technologies used in our industrial reeling and testing machines.

SPECIAL STANDARD FEATURES

✔ Dimensions 260x80cm

✔ Nominal roll ø30cm H185

✔ Adjustable speed up to 25m/min

✔ Voltage 230V single-phase

✔ Machine already mounted on wheels

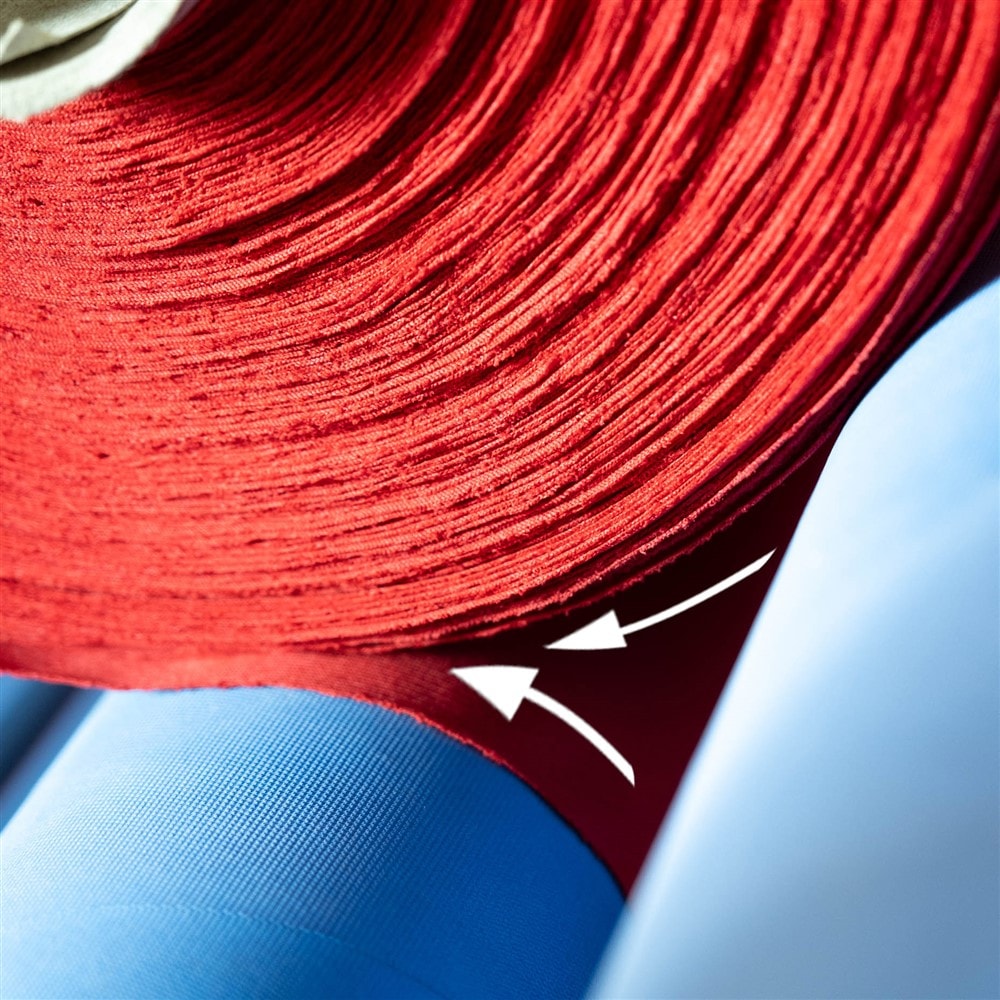

✔ Oil-resistant silicone roller coating, delicate but with high grip

✔ Barriers to keep the fabric aligned

✔ Special threading with fabric rising between the rollers for truly compact rolls

✔ The side seen during unwinding is wrapped and protected inside the roll

✔ Support for unwinding rigid fabric rolls on the shaft

✔ Low-friction bearings and alloy rollers

OPTIONS

✔ Automatic programmable meter counter

✔ Adjustable fabric tension with brake or motor

✔ Electric cutter with guide

✔ End-of-roll sensor for inventory or complete roll counts

✔ Polyethylene support bar for Packaging

✔ Fabric feed and packaging pedal

✔ Scale

✔ Inspection light above the fabric

We can also produce customized machines with larger dimensions

Alignment and grip

The rollers are wrapped with a special silicone tape that ensures excellent grip and oil resistance.

The very short travel distance and side panels allow the fabric to be rewound with its own alignment.

Compact winder with special draw-in

The fabric rises between the winding rollers; this way, the fabric is continuously pushed into the roll, allowing for truly compact rolls.

Options

Automatic metercounter

Automatic digital meter counter, programmable with automatic stop after 1 meter, and automatic slowdown to stop exactly at the desired measurement.

Also available with an RS232 serial output option for connection to your PC.

Counting sensor

The fabric presence sensor counts the meters only when there is fabric present, this way, it is possible to count the meters of fabric of the entire roll without errors.

Fabric cutting

The machine can be equipped with a battery-powered electric cutter mounted on a guide to make straight cuts.

Fabric tension adjustable

A brake can be installed on the unwinder to adjust the fabric tension.

For stretch fabrics or very heavy fabrics, a dedicated inverter motor is available to adjust the fabric tension.

Foot-pedal

With the pedal it is possible to advance the fabric manually and carry out roll packing operations

Polyethylene support bar for packaging

The polyethylene support bar allows the roll to be conveniently packed directly in the machine.

The maximum standard size is 200cm

(supports for wider widths can also be produced)

SERIES VARIANTS

Compact and quick-threading machine:

✔ The most compact of the series

✔ Quick drawing-in

✔ Allows for minimal fabric inspection before winding

Evolution of the AR PP 01 model, extended by 30 cm to allow fabric quality control during unwinding.

✔ Horizontal fabric control

✔ Black inspection table or lighted, tiltable (0°-15°)

✔ Fabric mending from the side

✔ Quick drawing-in

Evolution of the AR PP 02 model with a larger control table

✔ Large horizontal fabric control

✔ All-black or mixed light and black control table

✔ Side-facing fabric mending

✔ Quick drawing-in

✔ Vertical fabric inspection close to the operator

✔ Frontal fabric mending

✔ Optional adjustable-angle inspection table

✔ Bypass for inspection and quick drawing-in

✔ Vertical fabric inspection close to the operator

✔ Frontal fabric mending

✔ Optional adjustable-angle inspection table

✔ Bypass for inspection and quick drawing-in

Italiano

Italiano