A-FRAME preparation line

The machine mod. PRG allows you to join small 50m rolls into big 1500+m rolls, as well as check the quality of the fabric, eliminating defective fabrics before they are even processed.

At the heart of everything is the PREDICTIVE PRODUCTION concept: producing big batches, eliminating downtime and increasing the efficiency of the entire production sector.

The machine is designed to offer maximum efficiency and automation, allowing for the complete elimination of downtime for loading rolls, which are loaded in automatic or by the operator while the previous roll is being unwound. Furthermore, thanks to the "future preparation system" which allows for the preparation of the new fabric roll while the previous roll is being unwound, it is possible to save up to 480 minutes each day (25 seconds each seam).

With an unwinding speed up to 150m/min in the top version, the machine can produce at an average speed of 70 to 120m/min!

Easy to use even by inexperienced operator, the cutting and sewing system automatically sews the fabric heads, allowing the head and tail of the rolls to be joined together.

Perfect alignment of fabrics saves money; by joining the roll with the same orthogonality and tension along its entire width it is possible to print or process the roll from start to finish reducing material waste and defects.

SEWING TYPES

FLAT STITCHING

The flat stitching is perfect for all fabrics, delicate and durable.

The flat stitching allows the fabric to be wound without marking the other layers of the roll.

It also allows for use in machines where the stitching could get caught, such as in printing press heads.

It is available with a standard 18mm overlock stitch or a special overlock stitch up to 35mm.

CHAIN STITCHING

The chain stitching is perfect for fragile fabrics such as TNT (tessuto NON tessuto) subject to strong tension and allows you to join fabrics with a very internal seam line.

CUCITURA SOPRAGGITTO

The overlock stitching is used for fabrics with a variable structure that do not lend themselves well to chain stitch or flat stitching, such as lace.

Automatic loading of small fabric rolls

Efficiency also means reducing downtime, which is why we've eliminated the roll loading phase.

Thanks to the tilted table or conveyor belt, the operator doesn't have to worry about lifting the heavy rolls one by one and loading them into the unwinder.

The operation can be further automated with an automatic basket tilter.

What if you could earn 50% more?

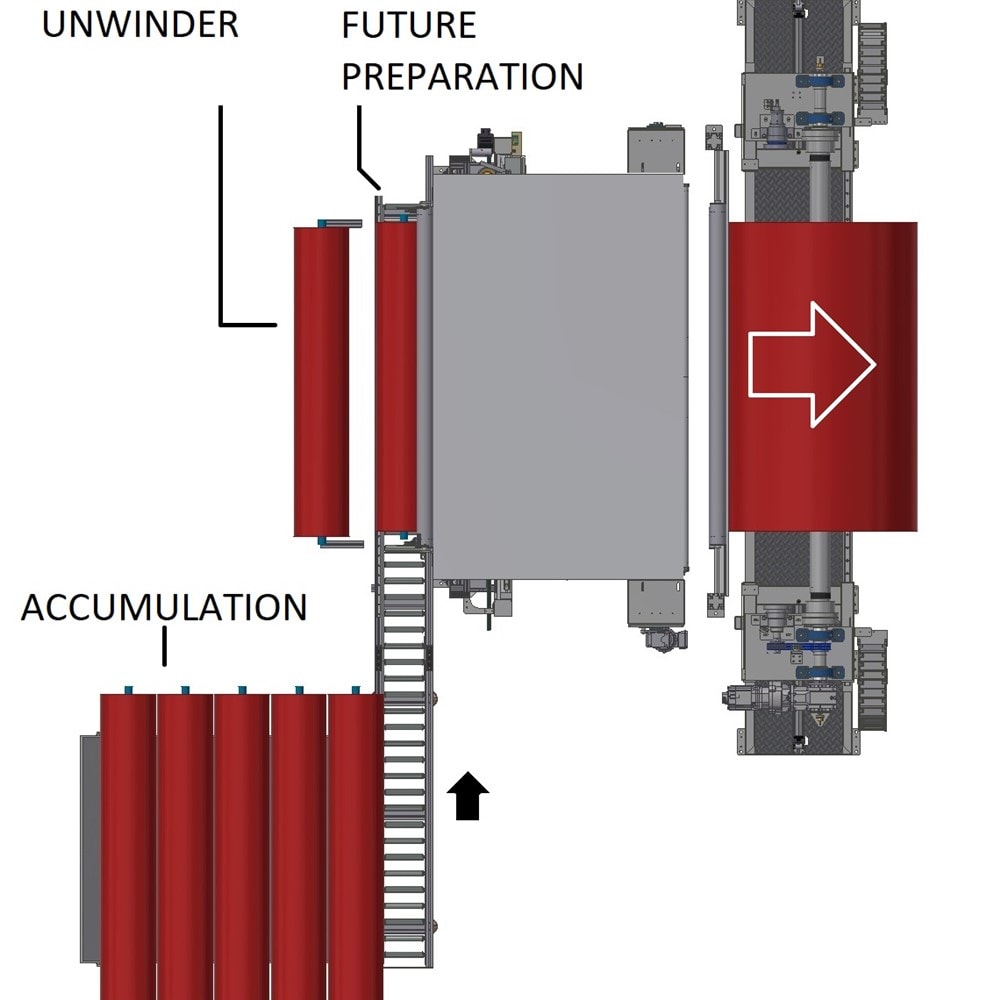

The Future Preparation System is an innovative system that reduces sewing time by 25 seconds, allowing for a further 15 to 50% increase in productivity.

Thanks to an additional intermediate unwinding position, the operator prepares the next roll while the previous one is still unwinding and inserts the edge of fabric into the sewing track. During sewing, the roll is moved to the actual unwinder, ready to start as soon as the fabrics are joined.

This system saves up to 480 minutes per day (25 seconds per seam).

Fabric joining and quality control

The inspection table allows you to inspect the fabric with front and backlighting to highlight the texture. For our high-end machines, we use dimmable LED lights with a very high color index; the light can be white or adjustable from warm to cool.

The Join-rail overlocking track moves and sews the edges automatically; the fully-accessorized Ultra-kit version features triple stapling, an automatic chain-cutter, an extra cutter, and a strap to support the edges of lightweight fabrics.

The sewing track also allows you to join first choice fabrics, removing defective sections without affecting production.

Fabric accumulation 3in1

For high production, the use of a buffer is recommended. During this important phase, the fabric is deposited in a J-shaped frame called "J-Box."

This system is recommended for increasing productivity and improving efficiency.

• The fabric relaxes any residual tension.

• The buffer allows the big roll in the exit to be changed without stopping the unwinder, saving up to 60 minutes per day.

• The winder operates at a constant speed without continuous start-stops and variations in fabric tension during downtime.

For technical fabrics, buffers with crossed sliding rollers can also be used.

This system is not necessary if the machine only needs to produce plait fabric.

Unloading area

The machine's exit can be in various forms:

• Roll on an A-frame carriage for woven or knitted fabrics

• Roll on cardboard, typically used for technical fabrics

• Free-fold for knitted fabrics

The winder can be combined with multiple systems: contact, non-contact, etc.

Before winding, the fabric is spread and aligned.

For fabrics with a felled selvedge, we can also include systems for zigzagging and trimming the selvedge or cross-cutting.

Cutting unit for tirmming

The perfect solution for trimming roll ends if they're too crooked.

It's also available in fully automatic and/or enhanced versions for very heavy fabrics.

Triple clamping for perfect alignment

Full-height clamping secures the fabric and prevents it from shifting during sewing.

Side clamping allows for perfectly aligned fabric edges and automatically stops the sewing machine.

The clamping can be manual (standard) or, for highly automated systems, with automatic fabric movement and tensioning.

Special needle clamping is also available upon request.

Automatic fabric-waste aspiration

The fabric waste is automatically sucked up and collected directly in a bin under the sewing machine, avoiding the operator having to throw it by hand into the bin every time, saving up to 30 minutes a day (3 seconds per stitch).

Automatic fabric support

The fabric is automatically supported beyond the stapling bar by a special belt.

This system is extremely useful for lightweight fabrics that would otherwise sag, and it allows for more uniform stitching.

It automatically guides the fabric continuously through the sewing machine, without operator intervention.

Automatic chain cutter and vacuum cleaner

The machine automatically cuts the chain stitch at the end of the seam, allowing you to speed up your work and save up to 30 minutes a day (3 seconds per seam).

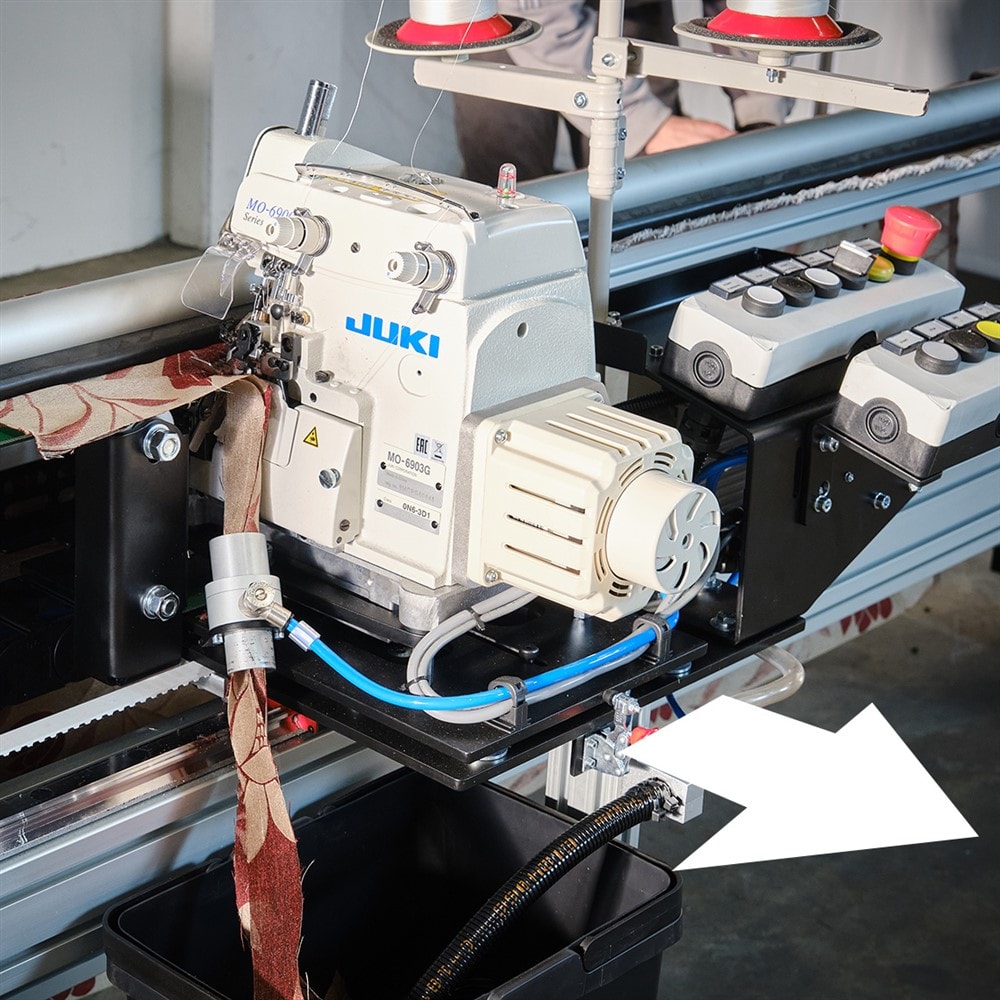

Pull-out sewing machine

The sewing machine is mounted on sliding guides, you can take out the machine in 5 seconds without tools to thread the thread or change the needle.

Italiano

Italiano