ATX F | Slitting for tubular on the bend line with open width inspection and exit in plait

Slitting for tubular fabric with inspection in plait

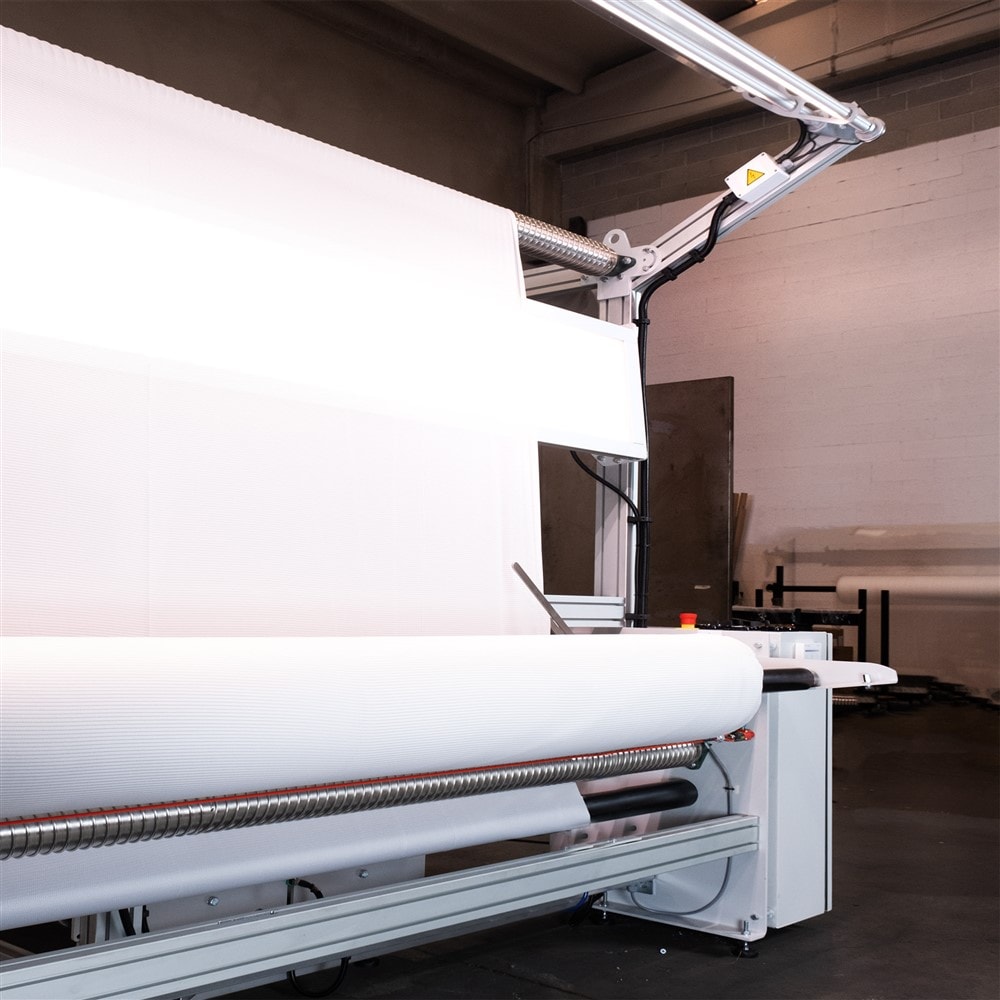

The machine mod. ATX F is the variant of the ATX machine for tubular raw fabric slitting complete with inspection table and double exit, in roll or in plait.

Simple to use, it allows companies that produce tubular fabric to open the fabric and perform an initial quality check without having to send the roll to third parties.

The heart of the machine is the continuous cutting of tubular fabric, performed by a ø200 motorized blade complete with integrated blade sharpener. The machine's design and special fabric-way allow the blade to perform a continuous cut along the plait line of the fabric, without any electronic control systems.

A triangle allows the fabric to be opened before inspection.

The inspection system, like quality control machines, consists of a black wooden table (optional), a dimmable light table, and external lights to illuminate the fabric from above.

The machine is completed by some selvedge decurling systems such as spreading rollers, widening combs also called “fingers” and compressed air systems, specifically designed to ensure that the selvedge does not curl during winding.

The machine output can be in wrapping, which occurs on paper tube that rotates over a motorized drive roller, or in folding, which is performed behind the operator who in this case will be positioned on an intermediate platform between the inspection area and the plaiting unit.

The operator therefore cuts, opens and checks the raw fabric in a single operation.

Italiano

Italiano