AUTOMATIC CAMERA VISION

AND INSPECTION SYSTEMS WIHT AI

Vision system that identifies the defects before the standard inspection table, leaving the operator with the task of instructing the software in progress by confirming or ignoring the reported ones

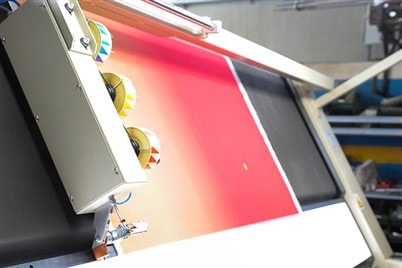

DEFECTMARKER

AUTOMATIC LABELLER FOR FABRIC DEFECTS

Automatic faults marker unit with up to three different labels, auto centering, it follows the edge of the fabric to aplly the labels in the exact position of the fault. It is ready to be add to an existing machine

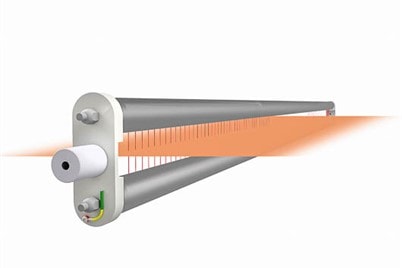

WIDTH SENSORS

WIDTH SENSORS FOR FABRICS IN CONTINUOUS

Fabric width sensor for all type of fabrics, transparents too. Symple to install, with data exchange module in order to exchange the data with the customer PC and software

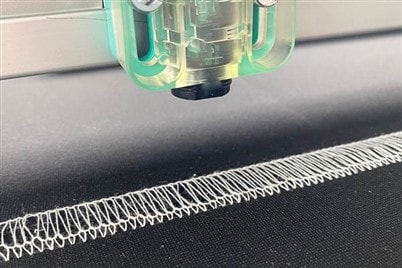

SEAM SENSOR

WITH AUTOMATIC SLOW-DOWN AND STOP

Seam sensor for all fabric with automatic slow-down or automatic stop of the machine, available with optical fiber technology

WINDING MACHINE

WITH METERCOUNTING AND AUTOMATIC STOP

Winding machine, super compact and easy-to-use, with roll unwinder and rewinder and electronic meter counter. Manual unloading and cutting unit with small inspection area

WINDING MACHINE

WITH TILTING INSPECTION TABLE

Winding machine, super compact and easy-to-use, with roll unwinder, tilting inspection table, winder and electronic meter counter. Manual unloading and cutting unit

WINDING MACHINE

WITH INSPECTION TABLE OVER THE WINDING

Winding machine, super compact and easy-to-use, with roll unwinder, tilting inspection table over the winding area and electronic meter counter. Manual unloading and cutting unit

STANDARD INSPECTION MACHINE

WINDING IN FRONT OF THE OPERATOR

Inspection machine very compact and symple to feed-in, ideal for the inspection roll to roll, allows to control both side of the fabric at the same time

STANDARD INSPECTION MACHINE

WINDING BEHIND THE OPERATOR

Inspection machine for high productions. The operator is situated between the inspection table and the winding unit, ideal position for the inspection, the mending and the unloading on packing line

SPECIAL INSPECTION MACHINE

WITH INSPECTION TABLE FOR MENDING

Inspection machine ideal for the mending of fabrics, thanks to the inspection table positioned close to the operator. For accurate inspection of both sides of the fabric

SPECIAL INSPECTION MACHINE

WITH INSPECTION TABLE IN PLANE

Inspection machine, simple to feed-in, with adjustable inspection table up to plane position, can be used for the inspection roll to roll and the cutting of all type of fabrics

TENSIONLESS INSPECTION MACHINE

WITHOUT TENSION AND AUTOMATIC FABRIC FEED-IN

Inspection machine, with automatic feed-in of the fabric, it can be used for the inspection roll to roll and the cutting of knit fabrics thanks to the special system that check the fabric tension

TENSIONLESS INSPECTION MACHINE

WITH FABRIC RELAX AND AUTOMATIC FABRIC TENSION

Inspection machine for superstretch fabrics; with vibrating conveyor belt up to 12m of relaxation, automatic tension adjustment and winding in front of the operator

TENSIONLESS INSPECTION MACHINE

WITH FABRIC RELAX AND AUTOMATIC FABRIC TENSION

Inspection machine for superstretch fabrics; with vibrating conveyor belt up to 24m of relaxation, automatic tension adjustment and winding behind the operator

TENSIONLESS INSPECTION + PACKING

COMPLETE LINE WITH AUTOMATIC UNLOADING

High performance line with tensionless inspection and packing machine in line. The operator is between the inspection table and the winding unit for the check of the fabric and automatic packing

Italiano

Italiano