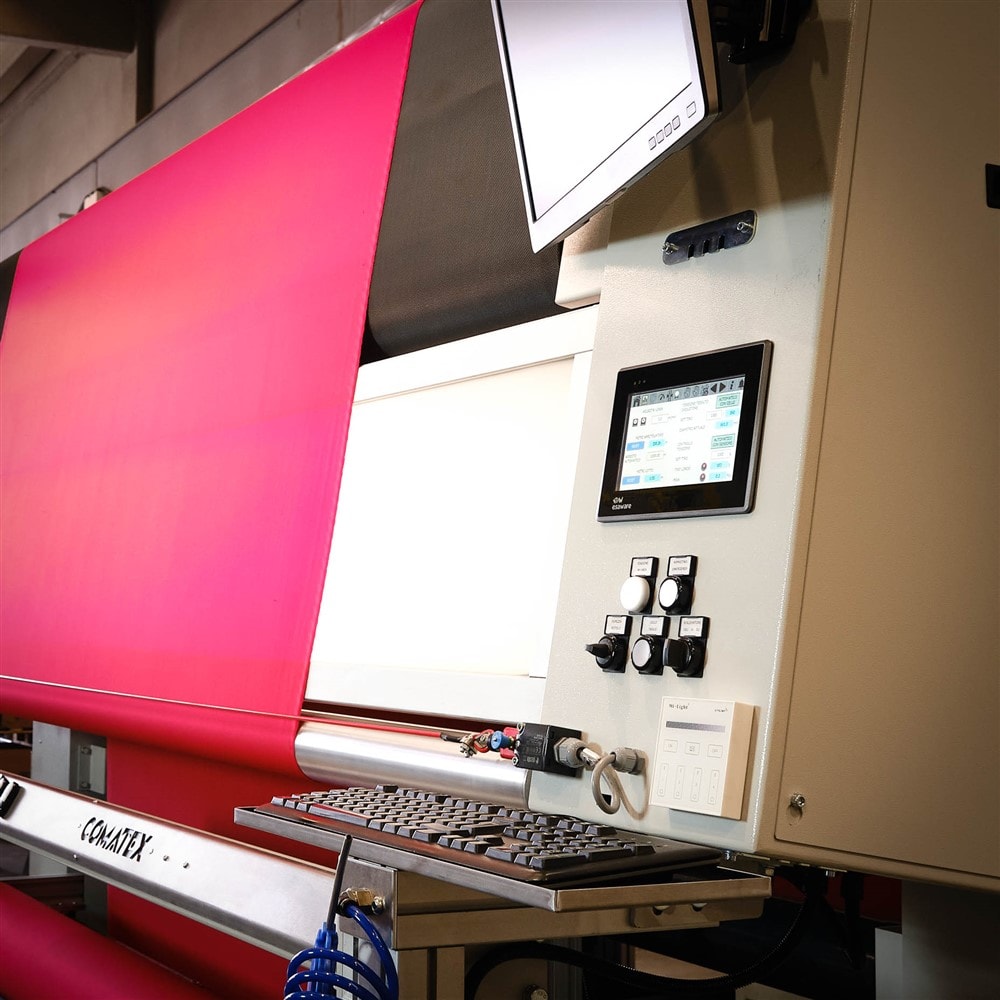

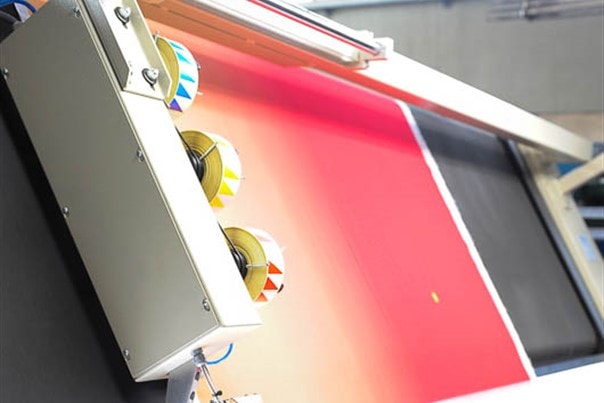

Inspection machine with inspection close-up

ISQ is a high performance machine for inspect the open width fabrics; whether it is knitted, woven or technical fabric, like each of our products it is customized according to the specific needs of the customer.

The machine is equipped with all edge alignment systems, as well as an innovative meter counter system, which allow it to produce high quality fabric rolls with excellent tension control.

COMPARED TO STANDARD MODELS, IT HAS A CHECK TABLE ABOVE THE ROLLER THAT ALLOWS TO SEE THE FABRIC CLOSE UP

STANDARD SPECIAL FEATURES

✔ Adjustable fabric tension

✔ Alignment of the fabric edge proportional to the machine speed (with drive)

✔ Adjustable roll hardness

✔ Special system for precise meter reading

✔ Speed up to 35m/min or higher at request

✔ 60° viewing angle with adjustable temperature and dimmable LED lights

✔ The inspected side is wrapped protected inside the roll

OPTIONS

✔ Automatic tension adjustment with load cells recommended for stretch fabrics, or with dancing roller recommended for rigid and stiff fabrics

✔ Rollers and spreader systems to spread out the fabric and uncurl his selveges

✔ “Reverse” winding the inspected side is wound on the outside of the roll

✔ PC with label inspection and printing software

✔ Automatic defect marker with label on the fabric

✔ PLC Touch screen and smart Kit

✔ Width sensor

✔ Roll weigh sensor

✔ Cross cut

✔ Multi-cutting and selvedge trimming

✔ Joinning stitching machine for joining the rolls at the entry

✔ Metal detector

MACHINE ENTRY

ENTRY IN ROLL ON PAPERTUBE

The roll entry is an excellent solution for the quality re-check of the fabric

The unwinding is done on two driven rollers with side barriers to avoid the movement of the roll

But it can also be done with a contactless axial system

PLAIT ENTRY

ENTRY FROM BIG BATCH

Of all the solutions, the machine entry from a big batch is the best solution for large quality productions; the fabric does not suffer creases, it remains compact, the number of joints and machine stops throughout the production cycle is reduced to a minimum.

But large masses require large controls, which is why we have included our best system, with which

It is possible to unwind the roll by setting the desired grams of tension

The load cell sensors continuously weigh the grams of the fabric and the roll

The PLC self-regulates to maintain the tension set in the touch

ENTRY ON-LINE NO-STOP

The non-stop is the most efficient solution when you want to produce and inspect rolls directly after the customer's production machines (Rameuse or Compactor)

It allows you to obtain multiple advantages

• Eliminates the cost of storing rolls

• Eliminates the roll change pauses at the exit of the production machine

• Eliminates the joining times at the entrance of the inspector

The inspection machine is positioned directly after the customer's machine

The fabric is picked up by the machine at the same speed as the production machine

During the pause for cutting the roll, the fabric is accumulated in a chute called J-box and then emptied at a higher speed

INSPECTION

FOR THE BEST INSPECTION

For the inspection unit we spared nothing, the lighting is managed by LEDs with very high color rendering that allow you to control every fiber of the fabric

• Very high CRI color index RA >95

• Adjustable light power

• Antiglare lateral curtains

• High lumen/watt efficiency for greater energy savings

Among the many options other options available

• Adjustable light temperature from warm to cold

• UV black light and cross lights

• Graphic cover to isolate the table from external lights

• Backlighting that can be darkened beyond the sides of the fabric

• Cross laser to check the warp and weft parallelism

• Light strip of 1 cm to check the microperforations

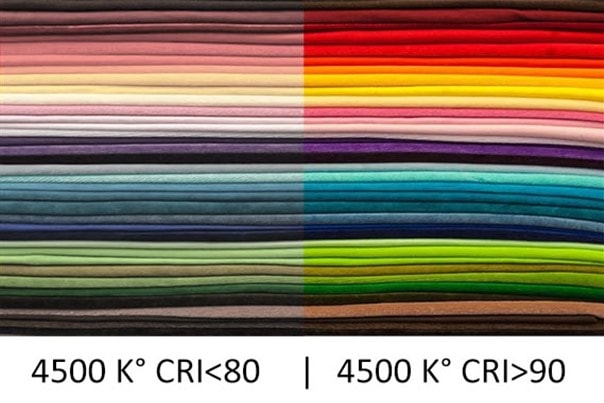

Quality of light

NOTHING IS LEFT TO CHANCE

Very high color rendering CRI >95

We have left nothing to chance, where others only look at temperature and lumens, we have looked beyond and also aimed at color quality.

We only use graphic quality LEDs, with very high color rendering, with a color index higher than Ra >95

Low color index lamps would show flat and dull colors; with our lamps it is possible to see all the color shades, detect dye variations while tiring the operator less

What sense would there be in an inspection machine that does not inspect all the colors?

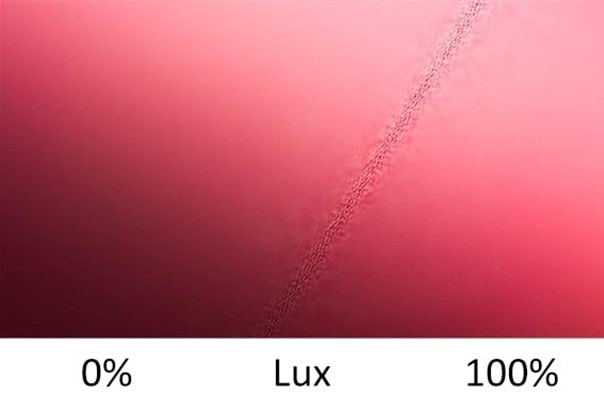

Adjustable light output

To avoid the operator being unnecessarily dazzled, we use only dimmable LEDs, so that adjusting the right brightness improves the quality of fabric control and therefore reduces fatigue

The light is adjustable

• Behind the fabric up to 5000 Lux

• Above the fabric up to 1200 Lux

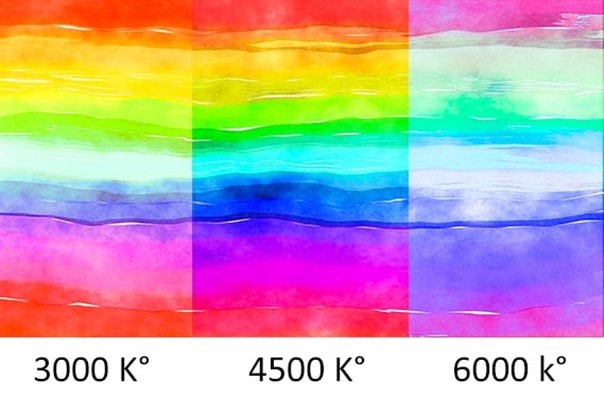

Color filter with adjustable temperature Warm→Cold

To reduce operator fatigue and increase detection of the faults

you can purchase the option to adjust the light temperature to your liking, without limits from 3000 K° up to 6000 K°

With the advantage of

• Increase contrast for red / blue fabrics

• Reduce operator glare caused by fluorescent colors

Winding in front or back?

Whatever your need, we have the solution

WINDING IN FRONT OF THE OPERATOR

Winding in front of the operator is the most compact solution, and is used in those contexts where it is necessary to keep both sides of the fabric under control:

✔ Control of both sides of the fabric

✔ More compact machine

✔ Quick installation

✔ Quick insertion of the fabric

✔ Length of the lower fabric path

Machine dimensions 125cm

+ 80cm space for operator and unloading

+ 80/120cm space for loading

Our machines with rolling behind the operator are the ISN, ISQ, IST, ISR, ISW

WINDING BACKSIDE THE OPERATOR

The winding behind the operator is the most complete and efficient solution for fabric inspection and offers the following advantages:

✔ Higher productivity

✔ Closer fabric inspection

✔ Winding of larger rolls without interfering with inspection

✔ Convenient and fast unloading on table or packing

✔ If combined with a packing machine the operator continues to inspect during packing

✔ Possibility of installing a folder

Machine dimensions 250cm

+ 80cm space for basket or unloading table

+ 80/120cm space for loading

Our machines with rolling behind the operator are the ISP, ISZ, ISX

TECHNICAL CHARACTERISTICS

CONCENTRATE OF TECHNOLOGY

The machine is equipped with the best technologies to optimize the production of fabric rolls

✔ Adjustable fabric tension

✔ Automatic edge alignment

✔ Adjustable roll hardness

Spreading rollers

To ensure fabric inspection and rolling without curled selvedge (cigarette effect)

The machine can be equipped with multiple spiral speading rollers, the rotation speed is normally fixed but can also be made adjustable by the PLC or proportional to the machine's working speed.

For raw fabrics we also have kits to unroll the selvedge with air blowers.

Edge alignment

In order to obtain high quality winding, the machine is equipped with an edge following sensor and an automatic alignment system.

Centering occurs by moving the winding carriage mounted on precision tempered guides and a linear actuator shielded from dust.

Movement speed proportional to the machine's working speed

Effective control even with semi-transparent fabrics

Fabric tension control

Our inspectors are equipped with precision fabric tension controls. The rollers that transport the fabric are equipped with inverters and regulators that allow the operator to wind the fabric with the desired tension.

In addition, for all machines that have to work with stretch and very light fabrics, we use aluminum rollers special bearings with very low friction

Adjustable roll hardness

The winding rollers have different and adjustable speed, you can adjust the winding torque to make the roll soft or hard.

Precision metercounter

Meter counter and automatic meter stop are standard in all our verification machines.

Thanks to the precision tension regulation and our special counting system the readings are precise and error-free *

It is also possible to connect it to the PC to continuously read the data via the optional card

Unloading position

After the winding unit, two pairs of rollers are installed that allow for easy closing of the roll (e.g. cutting or weight reading, taping, etc.)

A central passage has also been provided to allow the operator to get close to the roll

Air noozle

An air gun is installed on board the machine by default to be able to blow the fabric

Powder powder coating

Our machines are powder coated with oven baking, which offers very high durability, resistance and low roughness (easy to clean)

Our standard color is RAL 7035 but we can also use custom colors

STANDARD OPTIONS

SMART KIT 4.0 FOR A 360° INTERCONNECTION

OPTION SMART KIT 4.0

The smart kit 4.0 option opens up a world of possibilities, thanks to the PLC the adjustments and all machine data are easy to do and are displayed on the Touch screen

The remote assistance is already included as standard; and can be connected to the customer's management system with an optional router

3-level digital speed adjustable by touch with numerous benefits

• Instant speed change with a selector switch to quickly switch between slow inspection speed, normal inspection, high speed rolling

• Adjustable in touch or by knob

• Greater productivity

FABRIC TENSION CONTROL ADVANCED TO THE GRAM!

LOAD CELL OPTION

By purchasing the Smart kit option and load cell tension sensors.

Grams of fabric tension are measured continuously

The PLC self-adjusts to maintain the tension set by the operator or the fabric recipe

Cross cutter

The machine can be equipped with an automatic or manual cutter

Roll weighing

Automatic roll weighing with RS232 serial output or integrated into the PLC

Chain stitch sewing machine to speed up the threading operations of the machine

Multi-beam photocell barriers that continuously detect the width of the fabric.

Our machines can be equipped with PC, monitor and printer and connected to our mapping and labeling software.

The system automatically reads all the information meters, weight, width fabric seam etc.

Automatic label tags applicator on the edge of the fabric, can be connected to the quality pro software

Italiano

Italiano