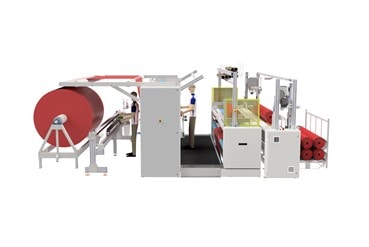

ISP | Inspection with winding backside

Related products

High performance machine

ISP is a high performance machine for inspect the open width fabrics; whether it is knitted, woven or technical fabric, like each of our products it is customized according to the specific needs of the customer.

The machine is equipped with all edge alignment systems, as well as an innovative meter counter system, which allow it to produce high quality fabric rolls with excellent tension control.

STANDARD SPECIAL FEATURES

✔ Adjustable fabric tension

✔ Alignment of the fabric edge proportional to the machine speed (with drive)

✔ Adjustable roll hardness

✔ Special system for precise meter reading

✔ Speed up to 35m/min or higher at request

✔ 60° viewing angle with adjustable temperature and dimmable LED lights

✔ The inspected side is wrapped protected inside the roll

OPTIONS

✔ Automatic tension adjustment with load cells recommended for stretch fabrics, or with dancing roller recommended for rigid and stiff fabrics

✔ Rollers and spreader systems to spread out the fabric and uncurl his selveges

✔ “Reverse” winding the inspected side is wound on the outside of the roll

✔ PC with label inspection and printing software

✔ Automatic defect marker with label on the fabric

✔ PLC Touch screen and smart Kit

✔ Width sensor

✔ Roll weigh sensor

✔ Cross cut

✔ Multi-cutting and selvedge trimming

✔ Joinning stitching machine for joining the rolls at the entry

✔ Metal detector

MACHINE ENTRY

ENTRY IN ROLL ON PAPERTUBE

The roll entry is an excellent solution for the quality re-check of the fabric

The unwinding is done on two driven rollers with side barriers to avoid the movement of the roll

But it can also be done with a contactless axial system

PLAIT ENTRY

ENTRY FROM BIG BATCH

Of all the solutions, the machine entry from a big batch is the best solution for large quality productions; the fabric does not suffer creases, it remains compact, the number of joints and machine stops throughout the production cycle is reduced to a minimum.

But large masses require large controls, which is why we have included our best system, with which

It is possible to unwind the roll by setting the desired grams of tension

The load cell sensors continuously weigh the grams of the fabric and the roll

The PLC self-regulates to maintain the tension set in the touch

ENTRY ON-LINE NO-STOP

The non-stop is the most efficient solution when you want to produce and inspect rolls directly after the customer's production machines (Rameuse or Compactor)

It allows you to obtain multiple advantages

• Eliminates the cost of storing rolls

• Eliminates the roll change pauses at the exit of the production machine

• Eliminates the joining times at the entrance of the inspector

The inspection machine is positioned directly after the customer's machine

The fabric is picked up by the machine at the same speed as the production machine

During the pause for cutting the roll, the fabric is accumulated in a chute called J-box and then emptied at a higher speed

INSPECTION

TECHNICAL FEATURES

A CONCENTRATE OF TECHNOLOGY

The machine is equipped with the best technologies to optimize the production of fabric rolls

✔ Adjustable fabric tension

✔ Automatic edge alignment

✔ Adjustable roll hardness

OTHER SPECIAL FEATURES FOR THE VERIFICATION MACHINE WITH PLATFORM

STANDARD OPTIONS

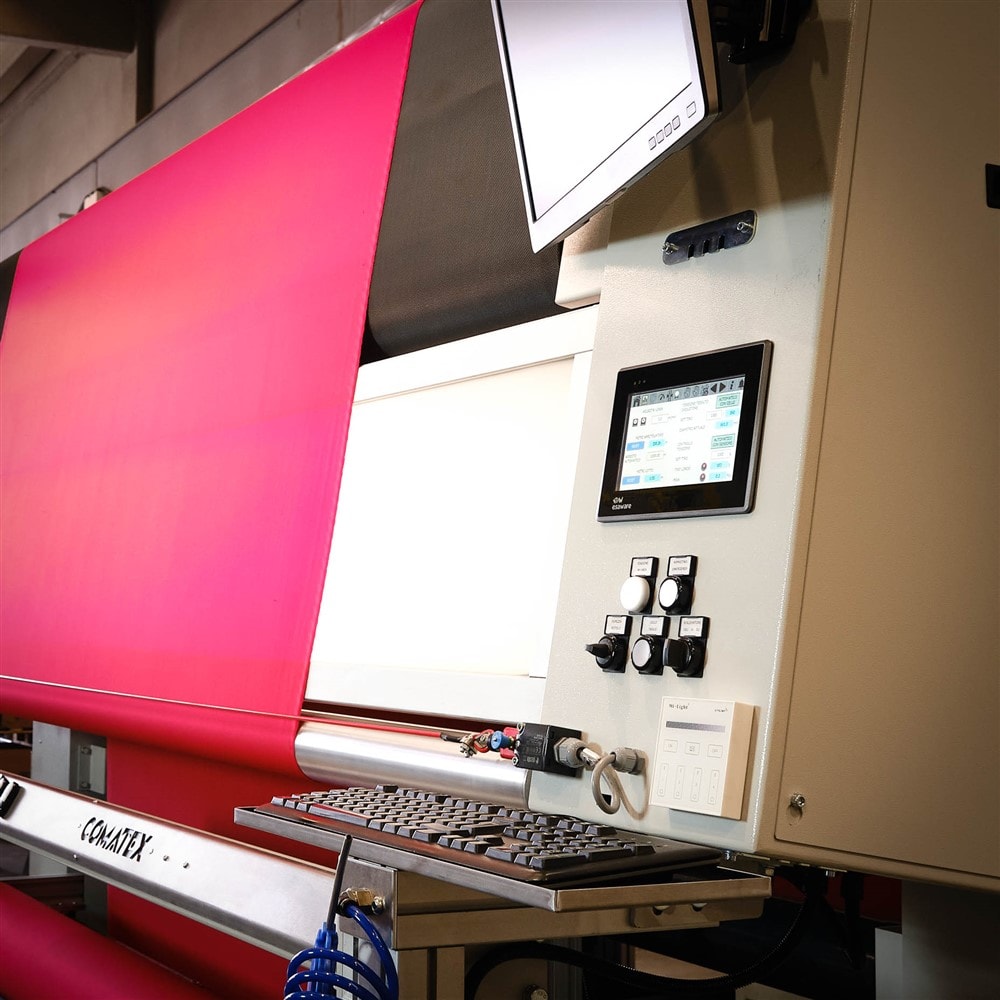

SMART KIT 4.0 FOR A 360° INTERCONNECTION

OPTION SMART KIT 4.0

The smart kit 4.0 option opens up a world of possibilities, thanks to the PLC the adjustments and all machine data are easy to do and are displayed on the Touch screen

The remote assistance is already included as standard; and can be connected to the customer's management system with an optional router

3-level digital speed adjustable by touch with numerous benefits

• Instant speed change with a selector switch to quickly switch between slow inspection speed, normal inspection, high speed rolling

• Adjustable in touch or by knob

• Greater productivity

FABRIC TENSION CONTROL ADVANCED TO THE GRAM!

LOAD CELL OPTION

By purchasing the Smart kit option and load cell tension sensors.

Grams of fabric tension are measured continuously

The PLC self-adjusts to maintain the tension set by the operator or the fabric recipe

Cross cutter

The machine can be equipped with an automatic or manual cutter

Roll weighing

Automatic roll weighing with RS232 serial output or integrated into the PLC

Chain stitch sewing machine to speed up the threading operations of the machine

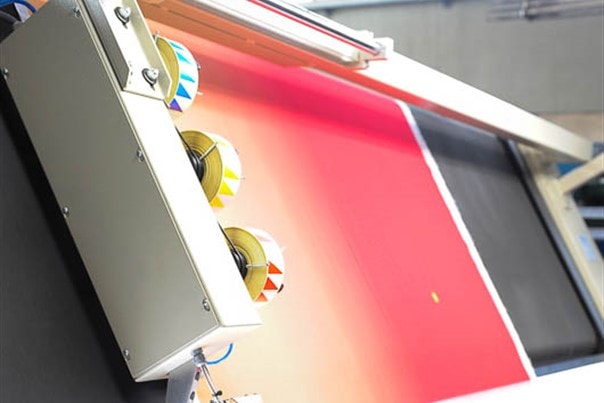

Multi-beam photocell barriers that continuously detect the width of the fabric.

Our machines can be equipped with PC, monitor and printer and connected to our mapping and labeling software.

The system automatically reads all the information meters, weight, width fabric seam etc.

Automatic label tags applicator on the edge of the fabric, can be connected to the quality pro software

Italiano

Italiano