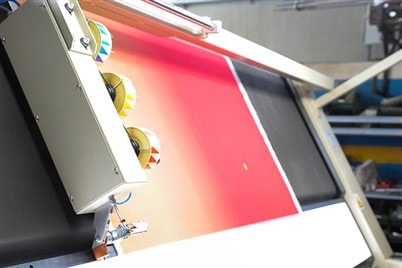

TUBULAR SEWING MACHINE

FOR THE DYEING PROCESS OF LYCRA FABRICS

Tubolare sewing machine to prepare the fabrig to the dyeing process with doubling and sewing. It risolves the dyeing troubles about the curled selvedges and improve the quality reducing the fabric waste

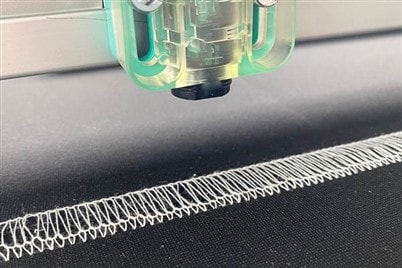

AUTOMATIC UNSTITCHING

THREAD WINDER WITH "Z" MOVEMENT AFTER DYEING

Automatic unstitching machine that allows to stich out the thread from the fabric, after the dyeing process. It is positioned just before the openrope machine and synchronized with its speed

ENDLINE WINDER

NO-STOP ENTRY WITH INSPECTION TABLE

Winding and inspection machine with NO-STOP entry, for the fabric winding in roll, ideal just after a compactor machine or other production machines as RAM

MULTI-SLITTING MACHINE

WITH UNWINDER AND REWINDER

Multislitting machine for the continuous cutting of fabrics or TNT, with differents unwinding and rewinding system and cutting units identified for each individual type of fabric to be processed

AUTOMATIC REWINDER

WITH METERCOUNTING AND ROLL CUTTING

Automatic winding machine for fabric roll equipped by different types of entry, with very accurate tension control systems and meter counting for automatic cutting

CRUSH CUTTING UNIT

FOR MULTI-SLITTING MACHINE

Pressure cutting unit for continuous multi-cut cutters, uses the pressure of a blade against a tempered counter-roller to cut any type of fabrics cleanly and optimally

SCISSOR CUTTING UNIT

FOR MULTI-SLITTING MACHINE

Scissor cutting unit for continuous multi-cut cutters, uses the contrast between a blade and counterblade to cut any type of fabrics cleanly and optimally

EDGES WINDER

FOR AUTOMATIC WINDER OF TRIMMED EDGES

Stand-alone unit or unit ready to be add at existing machine, for the automatic winder of trimmed edges with "Z" movement before the winding

INSPECTION SOFTWARE

FOR THE QUALITY CONTORL AND LABELLING

Customizable inspection software for the quality control of fabrics and label creator for packing list or laboel with main or detailed features

AUTOMATIC CAMERA VISION

AND INSPECTION SYSTEMS WIHT AI

Vision system that identifies the defects before the standard inspection table, leaving the operator with the task of instructing the software in progress by confirming or ignoring the reported ones

DEFECTMARKER

AUTOMATIC LABELLER FOR FABRIC DEFECTS

Automatic faults marker unit with up to three different labels, auto centering, it follows the edge of the fabric to aplly the labels in the exact position of the fault. It is ready to be add to an existing machine

WIDTH SENSORS

WIDTH SENSORS FOR FABRICS IN CONTINUOUS

Fabric width sensor for all type of fabrics, transparents too. Symple to install, with data exchange module in order to exchange the data with the customer PC and software

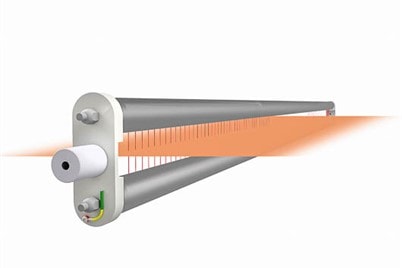

SEAM SENSOR

WITH AUTOMATIC SLOW-DOWN AND STOP

Seam sensor for all fabric with automatic slow-down or automatic stop of the machine, available with optical fiber technology

WINDING MACHINE

WITH METERCOUNTING AND AUTOMATIC STOP

Winding machine, super compact and easy-to-use, with roll unwinder and rewinder and electronic meter counter. Manual unloading and cutting unit with small inspection area

WINDING MACHINE

WITH TILTING INSPECTION TABLE

Winding machine, super compact and easy-to-use, with roll unwinder, tilting inspection table, winder and electronic meter counter. Manual unloading and cutting unit

Italiano

Italiano